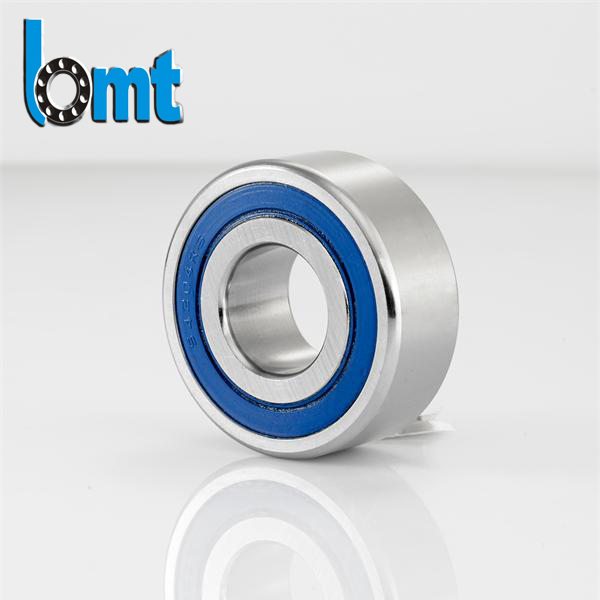

Thrust Ball Bearings: Key Components Of Efficient And Stable Mechanical Transmission

Date: 2025-06-14 Categories: Industry News Hits: 311

In the field of modern mechanical engineering, bearings play a vital role, and thrust ball bearings have been widely used in many equipment with their unique structural and performance advantages.

Structural features

Basic composition: Thrust ball bearings are mainly composed of a shaft washer, a housing ring and a set of steel balls. The shaft washer is usually mounted on the shaft, while the seat washer is mounted in the housing bore of the machine.

The steel balls are the core components that transmit the load, and they are held between the raceways formed by the shaft and the seat ring.

Mode of contact

Thrust ball bearings are point-contact structures. This type of contact allows it to effectively distribute pressure when subjected to axial loads. The contact point between each ball and the ring and the seat ring forms a small load transfer area, which is able to withstand large axial forces under the combined action of multiple steel balls.

Performance Benefits

1. High axial load capacity

Able to withstand large axial loads. For example, in the spindle system of some heavy-duty machine tools, thrust ball bearings can easily cope with axial forces of up to several tons, ensuring the stability and accuracy of the spindle at high speeds.

2. Low coefficient of friction

Thrust ball bearings have a low coefficient of friction due to the point contact between the ball and the raceway and good lubrication conditions. This helps to reduce energy losses and increase the efficiency of mechanical transmissions. In high-speed equipment such as turbine generators, the low-friction properties reduce heat generation and extend bearing life.

3. High-speed performance

It can be adapted to higher speeds. In some parts of aero engines, thrust ball bearings can still maintain good working condition under high-speed rotation to meet the requirements of the engine for high-speed performance of parts.

Fields of application

1. Machine tool industry

It is widely used in the spindle and workbench of CNC machine tools. For example, in the table feed system of the machining center, the thrust ball bearing can accurately bear the axial force to ensure the smooth movement of the table, so as to improve the machining accuracy.

2. Automobile industry

It is used in transmissions, differentials and other parts of automobiles. For example, in manual transmissions, thrust ball bearings help to withstand the axial impact forces when shifting, ensuring reliable shifting of the transmission.

3. Aerospace

It is used in key parts such as high-pressure turbine shafts for aircraft engines. In the attitude adjustment system of the space vehicle, the thrust ball bearing can also work stably under extreme conditions, meeting the requirements of reliability and accuracy of aerospace equipment.

Maintenance & Maintenance

1. Lubrication

It is essential to regularly inspect and replenish the grease or oil. Good lubrication can reduce the wear between the ball and the raceway and prolong the service life of the bearing. Different types of lubricants may be required for different working environments and load conditions.

2. Check for wear

Regularly inspect the thrust ball bearings to see if the steel balls are worn or deformed, and whether there are scratches on the raceways of the shaft and housing rings. Once abnormal wear is found, the bearing should be replaced in time to avoid greater damage to the entire mechanical system.

Thrust ball bearings play an irreplaceable role in many mechanical engineering fields with their unique structure and excellent performance. With the continuous development of mechanical technology, the performance of thrust ball bearings is also improving, and it will show its greater value in more high-end equipment and precision machinery in the future.

1606-2Z , 1606-2RS Single Row ...

1606-2Z , 1606-2RS Single Row ...  Spherical Roller Bearing D 200...

Spherical Roller Bearing D 200...  Clutch Release Bearing

Clutch Release Bearing  Air Condition Bearing

Air Condition Bearing  W N Series

W N Series  Motor Bearing

Motor Bearing